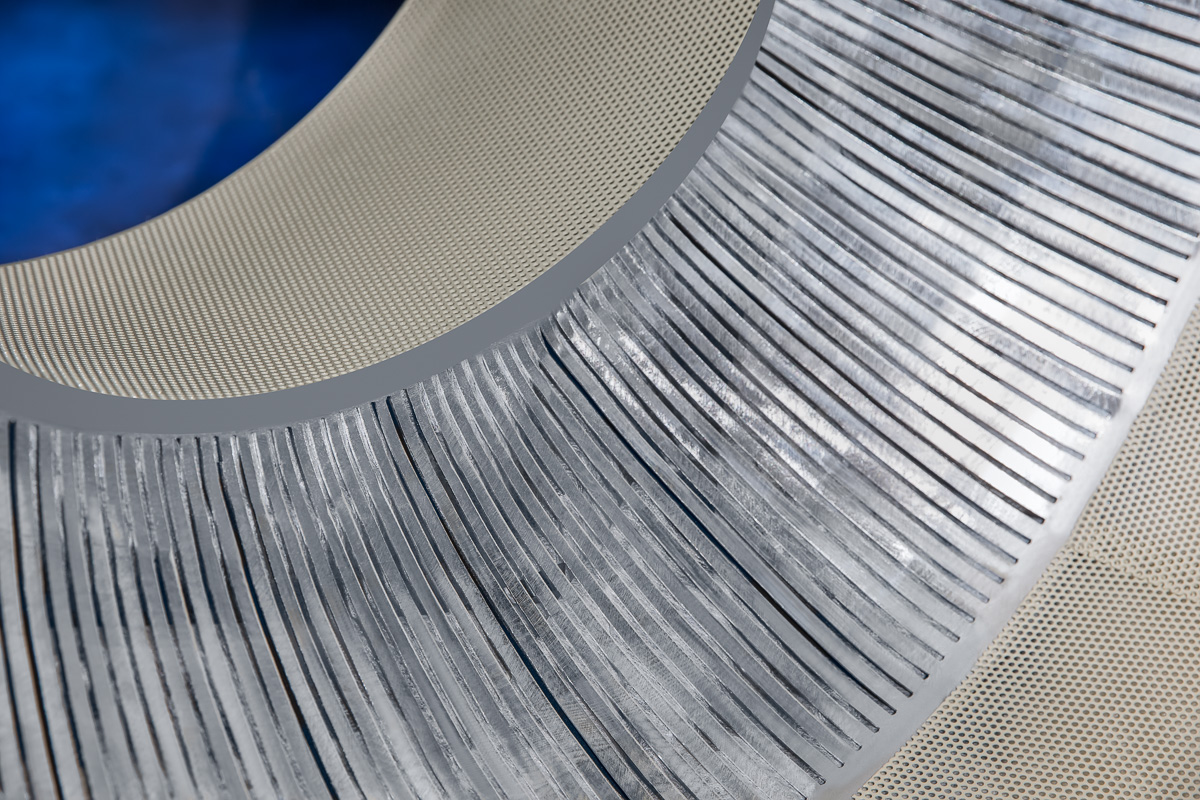

“One rotating part, no belts, sheaves or tensioners to fail or require adjustment...”

- Direct Drive

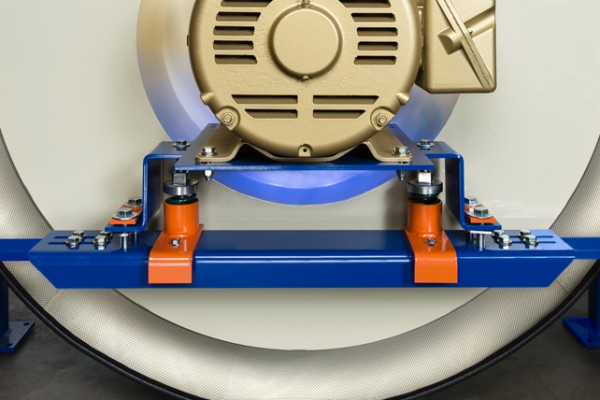

- Integral Spring Isolation

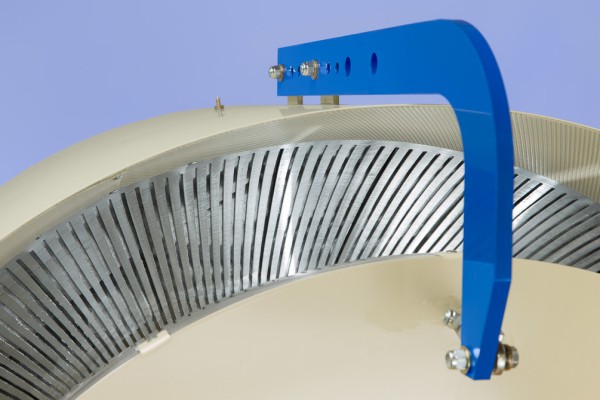

- Pressure Taps

- Lightweight Aluminum Fan Wheel

- Manageable Motor Sizes

Belts reduce motor bearing life by 65%.

Direct drive motors result in fewer dollars spent repairing or replacing belts, bearings and sheaves.

It’s inevitable that over time transmitted vibration causes mechanical parts to wear out requiring repair or replacement. Our integral spring isolation is designed to minimize vibration in the fan module and transmission of vibration to the building structure.

Individual fan flow measurement:

Every fan module is factory equipped with integral piezometer taps that are used to confirm initial factory performance and to allow integration into an on-site flow monitoring station, providing real-time flow and operation data from each fan in the array.