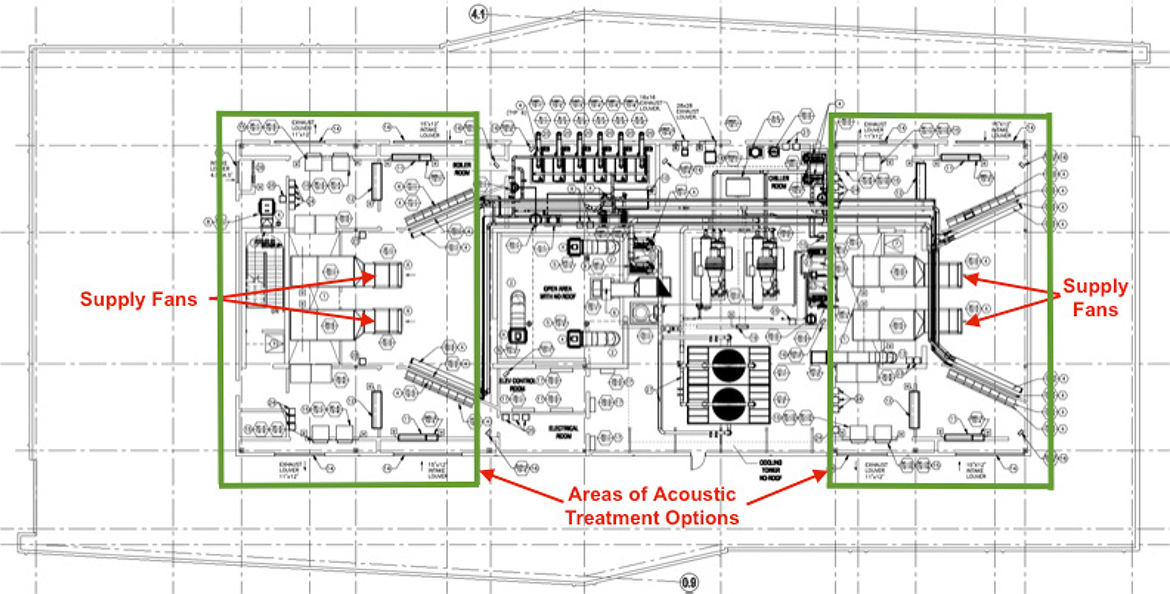

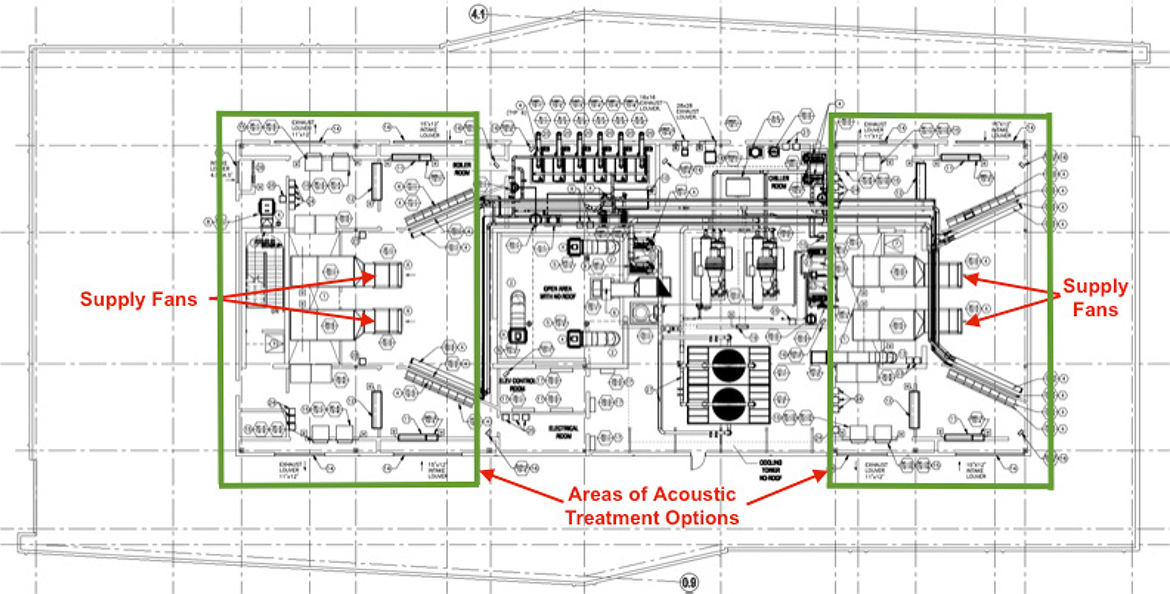

The developers of Central Park Tower were faced with a dilemma during the design of their new 11-story office tower in Broomfield, Colorado. The acoustic target for occupied office space in the new facility was NC 35-40. The primary air handling systems were designed on the 12th floor directly above the most expensive and desirable space in the building. Four 150 HP vane-axial supply fans were located within two conditioned air plenums above occupied office space.

Analysis of the calculated sound in the immediate areas of the 11th floor below the air handlers indicated a resultant level far exceeding the specified NC levels. Several solutions were offered by the acoustic consultant to mitigate the potential excessive sound levels on the 11th floor:

Lining of the outdoor air, mixed air, and conditioned air plenums with 2" thick fiberglass insulation combined with one of the following:

Select another fan system that will provide 157,500 CFM at 6.5" SP per fan room at significantly reduced sound levels.

The mechanical engineer contacted AcoustiFLO for an option to the four vane-axial supply fans. AcoustiFLO engineered a solution incorporating (20) 25HP 686q supply fans, (10) per fan room. This solution was accepted and incorporated into the new facility (see system photos).

The advantages of this solution are: