Replacing the primary air mover and upgrading the system presented several challenges and was attended by the need to improve efficiency and increase reliability. The owner’s requirements were:

The Wells Fargo Motor Bank is located in the heart of downtown Denver and is in a portion of a multi-building complex housing the regional headquarters of Wells Fargo Bank. This facility is regulated by both state and federal oversight requiring operations be staffed for a minimum of 21 hours per day five days per week and 12 hours on Saturday. The area occupied by the Motor Bank is in a part of the building constructed in the late 60’s. Much of this facility has been upgraded over the years, however the prime air handler, located 3-levels below the street was still served by a single 150 HP DWDI centrifugal fan installed when the building was constructed. Aging bearings and cracks in the main fan shaft had threatened several times to completely shut down heating and air conditioning service to the Motor Bank facility.

Replacing the primary air mover and upgrading the system presented several challenges and was attended by the need to improve efficiency and increase reliability. The owner’s requirements were:

Replace the large single fan with multiple fans with the capability to adequately serve the Motor Bank in the event of a single fan failure.

Improve the energy efficiency of the prime air mover.

Provide capability to vary the flow of the system to accommodate future replacement of constant volume terminal units with variable air volume boxes.

Replacement challenges and constraints:

The facility management company CBRE and Wells Fargo working with their consulting group Concord West and the selected mechanical contractor, American Mechanical Services, considered several options for replacement of the aging fan. Ultimately, after consideration of the features offered, the ability to meet the owner’s criteria, and ease of installation, AcoustiFLO modular fans were selected for the retrofit.

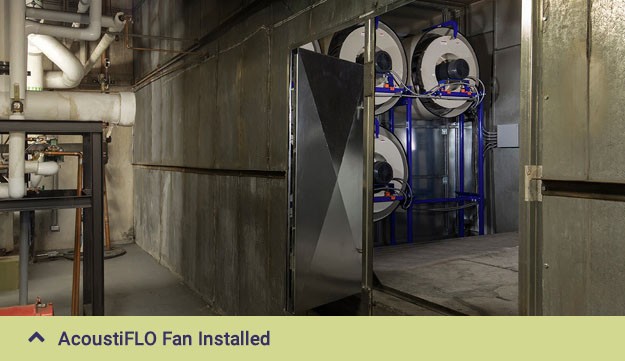

The existing fan was located within a sheet metal casing with filter banks on each side of fan and supply duct discharging through the side of the casing (Fig. 1).

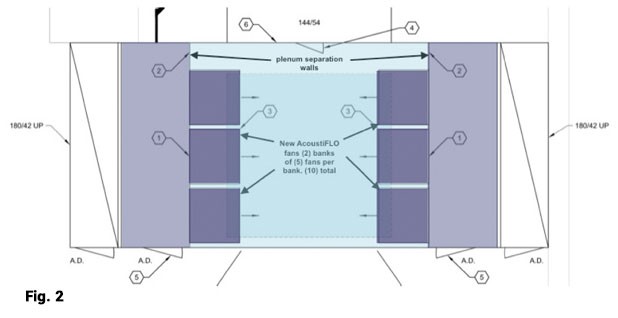

The new modular fans were installed in arrays on either side of the existing fan over two weekends (Fig 2). During the interim two week period, airflow from the filters flowed around and through the new fan array into the old fan. After completion of the arrays, and final electrical connections to the new fans, the old fan was cut into pieces and removed through the rear of the casing. Plenum walls were installed and sealed and the new fans started.

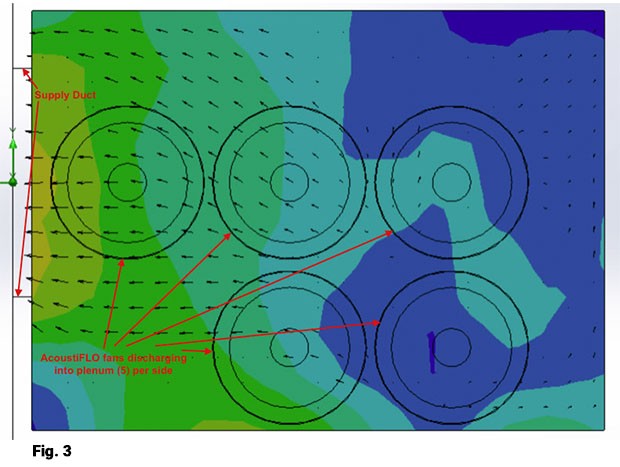

To confirm aerodynamic performance, AcoustiFLO created a graphic CFD analysis of the resultant flow in the plenum with (10) fans discharging into the plenum (Fig.3)

The retrofit was completed in three weekend work periods with the following advantages/features: